Aluminum Cable Testing Services

Aluminum Cable Testing Services Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- Piece

- Delivery Time

- As per Schedule Days

- Main Domestic Market

- All India

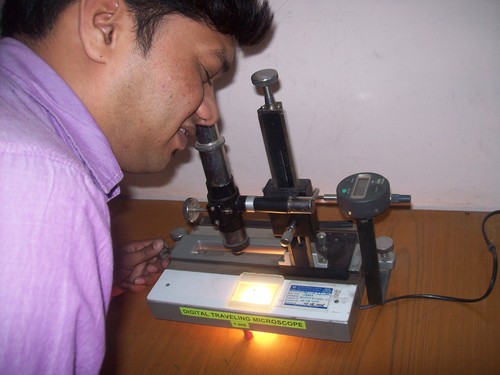

About Aluminum Cable Testing Services

We have earned a huge clientele across the nation by offering Aluminum Cable Testing Service to the clients. This service is high-on-demand for assuring the constant and reliable supply of the power through the aluminum wires installed at power transmission systems or electronic devices. In order to render this service, our adroit professionals use sophisticated testing tools that helps to detect the fault within minimal time. The provided Aluminum Cable Testing Service is extensively cherished by our clients owing to its budgeted price and hassle-free management

Product details

| Sampling Procedure | Off-Site Testing |

| Testing Type | ALL |

| Required Standards | IS:1554 PT. I & II |

| Conductor Type | Aluminium |

| Industry Type | ALL |

| Usage/Application | ALL |

Comprehensive Testing Capabilities

We offer thorough testing for aluminum cables, focusing on electrical conductivity, insulation resistance, and mechanical properties. Leveraging up-to-date digital and analog equipment, we ensure precise evaluations for cables up to 33kV. All services are compliant with IS and IEC standards for maximum reliability.

Flexible and Efficient Service Delivery

Testing services are accessible anywhere in India, with options for both laboratory and on-site assessments. We accommodate any standard cable size and use flexible batch or random sample methods. Clients receive reports quicklywithin seven working daysand can access data in both digital and paper formats.

Dedicated Support and Consultation

Our services dont end with just testing; we provide expert consultation after completion to help you understand results and address any quality or safety issues. All assessments are traceable and performed by NABL-accredited professionals for assured competence and transparency.

FAQs of Aluminum Cable Testing Services:

Q: How are aluminum cables tested for quality and safety?

A: Aluminum cables undergo electrical conductivity, insulation resistance, and mechanical integrity tests using advanced digital and analog meters. Testing follows IS, IEC, and client-specific standards to ensure quality and compliance.Q: What is the process and timeline for receiving the test report?

A: Cable samples are collected randomly or batchwise, tested in NABL accredited labs or on-site, and results are delivered digitally and in hard copy within seven working days after sample receipt.Q: Where can these cable testing services be conducted?

A: Testing services are available PAN India, either at our accredited laboratory or through on-site visits, depending on client requirements and project scope.Q: What types and sizes of aluminum cables can be tested?

A: Any standard size aluminum cable with a voltage rating of up to 33kV can be tested. Our processes are equipped to handle various industrial and commercial applications.Q: When should aluminum cables be tested?

A: Testing is recommended before installation, after repairs, as part of routine maintenance, or when assessing cable performance for quality assurance and safety compliance.Q: What benefits do these testing services offer?

A: Clients gain reliable data on cable quality, compliance with safety standards, and actionable insights via post-test consultation, helping prevent electrical hazards and ensuring uninterrupted operations.Q: How does traceability and standard certification ensure test reliability?

A: All tests are traceable to a NABL-accredited laboratory and certified as per IS/IEC standards, ensuring validity, transparency, and industry-accepted accuracy of results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry